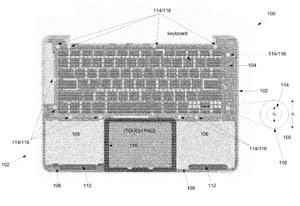

Apple has been granted a patent (number 20110088838) for self fixturing assembly techniques used in creating the “unibody” design of many Macs, including the portable line.

A process, apparatus, and system for joining at least two work pieces together using at least two adhesives each having substantially different cure times. A first adhesive having a first cure time is used to form a first bond between the two workpieces, the first adhesive having a first cure time.

A second adhesive having a second cure time, the second cure time being substantially shorter than the first cure time is used to form a fixturing bond. The fixturing bond maintaining the first and second workpieces in position prior to the first adhesive curing. The inventors are Peter M. Thompson, Martin Adamcyk, Timothy G. Van Vorhis, Arthur J. Lucchesi, Thomas A. Moore and Matthew B. Morris.

Here’s Apple’s summary of the patent: The outward appearance of a portable computing device, including its design and its heft, is important to a user of the portable computing device, as the outward appearance contributes to the overall impression that the user has of the portable computing device. At the same time, the assembly of the portable computing device is also important to the user, as a durable assembly will help extend the overall life of the portable computing device and will increase its value to the user.

One design challenge associated with the portable computing device is the design of the enclosures used to house the various internal components. This design challenge generally arises from a number conflicting design goals that includes the desirability of making the enclosure lighter and thinner, the desirability of making the enclosure stronger and making the enclosure more esthetically pleasing.

“The lighter enclosures, which typically use thinner plastic structures and fewer fasteners, tend to be more flexible and therefore they have a greater propensity to buckle and bow when used while the stronger and more rigid enclosures, which typically use thicker plastic structures and more fasteners, tend to be thicker and carry more weight. Unfortunately, increased weight may lead to user dissatisfaction, and bowing may damage the internal parts.

“Furthermore, in most portable computing devices, the enclosures are mechanical assemblies having multiple parts that are screwed, bolted, riveted, or otherwise fastened together at discrete points. For example, the enclosures typically have included an upper casing and a lower casing that are placed on top of one another and fastened together using screws. These techniques typically complicate the housing design and create aesthetic difficulties because of undesirable cracks, seams, gaps or breaks at the mating surfaces and fasteners located along the surfaces of the housing.

“For example, a mating line surrounding the entire enclosure is produced when using an upper and lower casing. Not only that, but assembly is often a time consuming and cumbersome process. For example, the assembler has to spend a certain amount of time positioning the two parts and attaching each of the fasteners. Furthermore, assembly often requires the assembler to have special tools and some general technical skill.

“Another challenge is in techniques for mounting structures within the portable computing devices. Conventionally, the structures have been laid over one of the casings (upper or lower) and attached to one of the casings with fasteners such as screws, bolts, rivets, etc. That is, the structures are positioned in a sandwich like manner in layers over the casing and thereafter fastened to the casing. This methodology suffers from the same drawbacks as mentioned above, i.e., assembly is a time consuming and cumbersome.

“Therefore, it would be beneficial to provide a housing for a portable computing device that is aesthetically pleasing and lightweight, durable and yet environmentally friendly. It would also be beneficial to provide operationally efficient methods for mounting computer sub-assemblies to the housing that preserves the aesthetic look and feel of the housing.”

— Dennis Sellers